Sandpaper is available for sanding by hand and for use with power tools. Here below is all about Sandpaper: Material, Performance, Grit.

Hand-sanding products allow for better control and give you the ability to reach areas that a power tool cannot. Sandpaper for hand sanding comes in various sizes including the widely popular 9 x 11 sanding sheet. You can use some sandpaper for both hand sanding and power sanding.

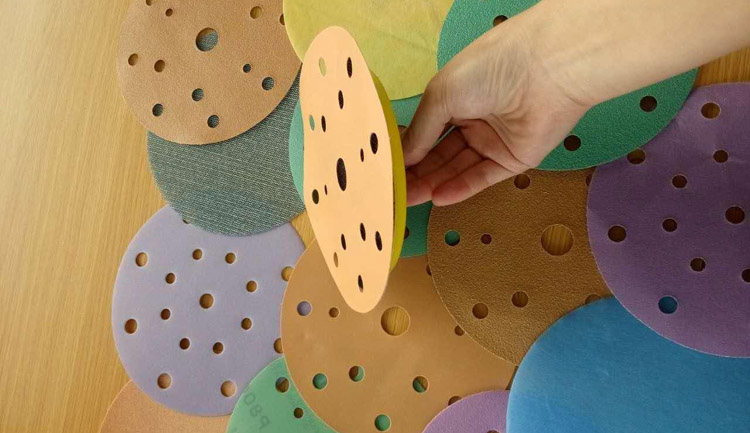

Power-sanding products remove material quickly and efficiently. They are a good choice for getting rid of blemishes and for shaping and leveling wood. Power sanding is an effective method of preparing metal surfaces for paint. Sandpaper for power tools comes in sheets, discs and belts designed to fit specific power tools.

One way to determine which sandpaper will work best for a particular job is to know the abrasive materials and their properties.

Commonly used manmade abrasives:

- Aluminum oxide is a common sandpaper type that works on wood, plastic, metal and drywall. The particles break during sanding, constantly exposing new, sharp edges. Aluminum oxide sandpaper is long lasting, making it a popular choice for power sanding, but you can also use it for hand sanding.

- Silicon carbide sandpaper removes material more quickly than aluminum oxide, but doesn’t last as long. Use it on wood, plastic and metal for tasks such as rough sanding, paint or rust removal and sanding between coats when finishing. Use it on drywall to smooth joints. Silicon carbide products often have a waterproof backing that allows you to wet sand. Wet sanding uses liquid to lubricate the work surface, minimizing scratches. This technique also helps prevent the sandpaper from clogging with dust, removes loose abrasive particles and reduces airborne dust.

- Zirconia alumina is suitable for wood, fiberglass, metal and painted surfaces. You’ll find it in the form of belts, pads and discs for power sanding. Like garnet and aluminum oxide, the particles break during use, maintaining sharp edges that remove material quickly. However, zirconia alumina lasts longer than aluminum oxide.

You may see sandpaper labeled closed-coat or open-coat. Closed-coat products feature abrasives covering all of the backing. This construction removes more material making it effective for hand sanding but can clog more quickly than open-coat products. Open-coat products have empty space on the backing, giving waste material room to accumulate without reducing performance. Since they don’t clog as quickly, they are effective for power sanding. Additionally some abrasive paper products come with a stearate coating which can reduce loading.

Good to Know

Paper is a traditional backing for sandpaper, but you can also find cloth and film backing, which offer better durability. Unlike products with paper backing, you can use cloth-backed or film-backed products for wet sanding as they are water resistant.

What is Grit?

The grit number of an abrasive sanding product indicates the size of the abrasive particles. The lower the number, the larger the abrasive particles — they remove more material but create more noticeable scratches. A higher number indicates smaller particles, which don’t remove as much material but leave a finer, more polished appearance.

Grit size ranges from 24 for heavy material removal to 2000 and beyond for working with automotive finishes. Grit numbers between 60 and 220 will handle most household projects.

The specific grit numbers you need vary by project and the material you’re sanding, so follow the abrasive product manufacturer’s recommendations.