Product Data:

| Model | JG-FD02 |

| Name | Calcined Aluminum Oxide Flap Disc |

| Material | Premium Calcined Alumium Oxide |

| Backing | Fiberglass Backing |

| Type | T27, T29 |

| Diameter | 2” – 9” |

| Grit | #40 – 120 |

| Code | Type | Size in mm | Size in Inch | Grit | Pages | Max Speed | Max. RPM |

|---|---|---|---|---|---|---|---|

| FP50#40 | T27 | 50 x 10 | 2" x 2/5" | 40 | 30 | 80 m/s | 15200 |

| FP50#60 | T27 | 50 x 10 | 2" x 2/5" | 60 | 30 | 80 m/s | 15200 |

| FP50#80 | T27 | 50 x 10 | 2" x 2/5" | 80 | 30 | 80 m/s | 15200 |

| FP50#120 | T27 | 50 x 10 | 2" x 2/5" | 120 | 30 | 80 m/s | 15200 |

| FP100#40 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 40 | 72 | 80 m/s | 15200 |

| FP100#60 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 60 | 72 | 80 m/s | 15200 |

| FP100#80 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 80 | 72 | 80 m/s | 15200 |

| FP100#120 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 120 | 72 | 80 m/s | 15200 |

| FP115#40 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 40 | 72 | 80 m/s | 13300 |

| FP115#60 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 60 | 72 | 80 m/s | 13300 |

| FP115#80 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 80 | 72 | 80 m/s | 13300 |

| FP115#120 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 120 | 72 | 80 m/s | 13300 |

| FP125#40 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 40 | 80 | 80 m/s | 12200 |

| FP125#60 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 60 | 80 | 80 m/s | 12200 |

| FP125#80 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 80 | 80 | 80 m/s | 12200 |

| FP125#120 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 120 | 80 | 80 m/s | 12200 |

| FP150#40 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 40 | 90 | 80 m/s | 10200 |

| FP150#60 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 60 | 90 | 80 m/s | 10200 |

| FP150#80 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 80 | 90 | 80 m/s | 10200 |

| FP150#120 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 120 | 90 | 80 m/s | 10200 |

| FP180#40 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 40 | 110 | 80 m/s | 8600 |

| FP180#60 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 60 | 110 | 80 m/s | 8600 |

| FP180#80 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 80 | 110 | 80 m/s | 8600 |

| FP180#120 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 120 | 110 | 80 m/s | 8600 |

| FP230#40 | T27, T29 | 230 x 22.3 | 9" x 7/8" | 40 | 128 | 80 m/s | 6000 |

| FP230#60 | T27, T29 | 230 x 22.3 | 9" x 7/8" | 60 | 128 | 80 m/s | 6000 |

| FP230#80 | T27, T29 | 230 x 22.3 | 9" x 7/8" | 80 | 128 | 80 m/s | 6000 |

| FP230#120 | T27, T29 | 230 x 22.3 | 9" x 7/8" | 120 | 128 | 80 m/s | 6000 |

| Size In mm | Inner Box | Carton | Carton Size(cm) | G.W/kgs | N.W/kgs |

|---|---|---|---|---|---|

| 50x10 | 20pcs/shrink | 500pcs | 28x28x24 | 12 | 11 |

| 100x16.3 | 10pcs/shrink | 100pcs | 55x23x15 | 7 | 6 |

| 10pcs/shrink | 200pcs | 55x23x27 | 14 | 12 | |

| 115x22.3 | 10pcs/shrink | 100pcs | 63x26x15 | 9 | 8 |

| 25pcs/shrink | 100pcs | 26x26x28 | 9 | 8 | |

| 125x22.3 | 10pcs/shrink | 100pcs | 68x28x15 | 11 | 10 |

| 25pcs/shrink | 100pcs | 26x26x28 | 11 | 10 | |

| 150x22.3 | 25pcs/shrink | 100pcs | 32x32x28 | 17 | 16 |

| 180x22.3 | 10pcs/shrink | 100pcs | 98x38x15 | 21 | 20 |

| 25pcs/shrink | 100pcs | 39x39x28 | 21 | 20 | |

| 230x22.3 | 25pcs/shrink | 50pcs | 48x25x28 | 18 | 17 |

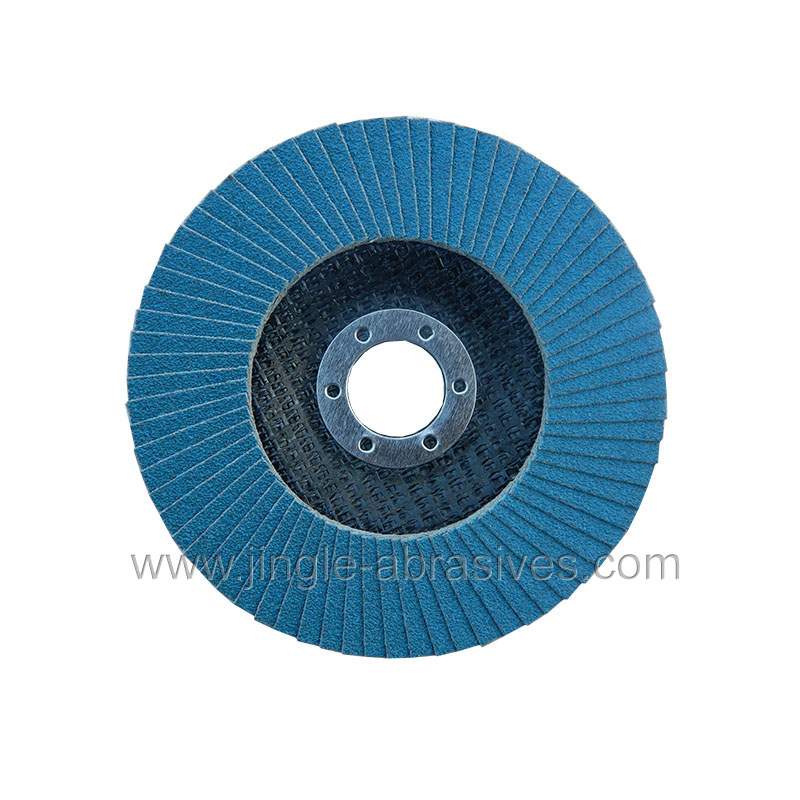

Calcined Aluminum Oxide Flap Disc is created by overlapping coated abrasive flaps and adhering them firmly to a back-up plate.This design provides a cooler running and longer lasting disc.The abrasive cloth is calcined aluminium oxide cloth. We all know that Aluminum oxide is the most widely used abrasives material. If we heated aluminium oxide to a temperature in excess of 1100ºC, then we call the final product as calcined aluminum oxide.Compared with traditional aluminum flap discs , the main advantages of calcined aluminium oxide is as below:

- Longer lifespan

- Sharper grinding ability especially for stainless steel.

- Higher thermal conductivity to avoid over heat on workpiece.

From an operator’s viewpoint, flap discs are preferred for several reasons. The discs are lighter weight, easier-to-control and have less downtime for product changes. Less vibration and resulting fatigue, as well as reduced noise, are also favored by operators.

Calcined Aluminum Oxide Flap Disc is specifically recommended for the processing of stainless steel, steel, metal, carbon steel, alloy steel, wood and plastic.