Product Data:

| Model | JG-FD04 |

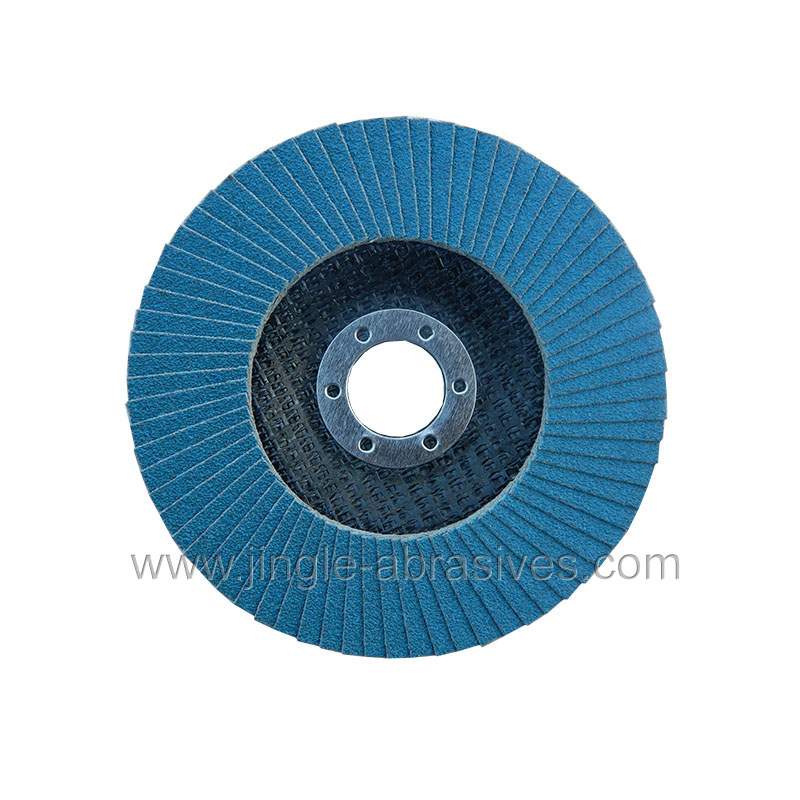

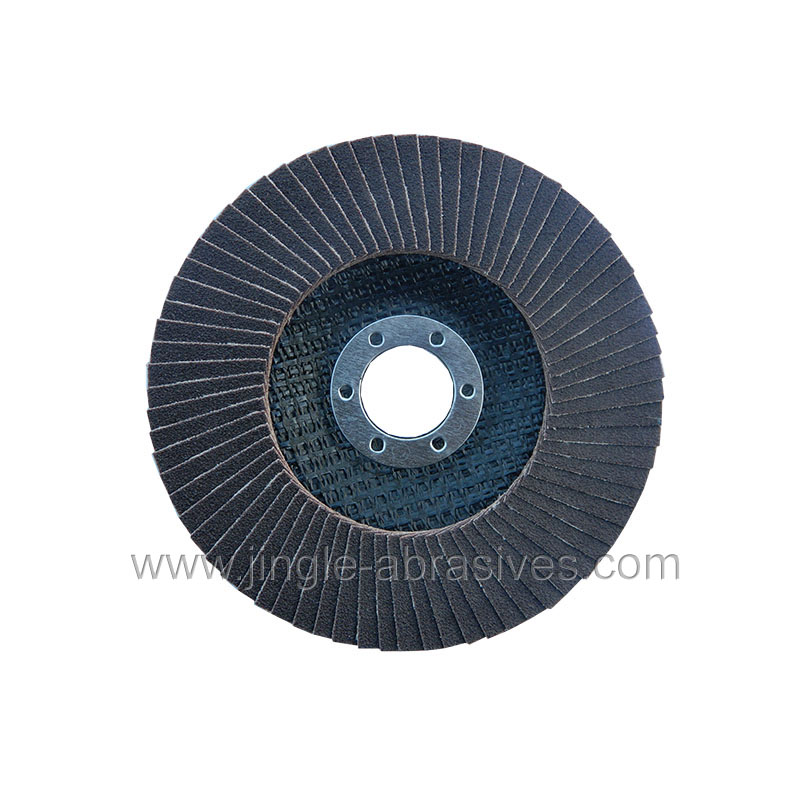

| Name | Ceramic Flap Discs |

| Material | Premium Ceramic Abrasives Grain |

| Type | T27, T29 |

| Backing | Fiberglass Backing |

| Diameter | 4” – 7” |

| Grit | #40 – 120 |

| Code | Type | Size in mm | Size in Inch | Grit | Pages | Max Speed | Max. RPM |

|---|---|---|---|---|---|---|---|

| CP100#40 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 40 | 72 | 80 m/s | 15200 |

| CP100#60 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 60 | 72 | 80 m/s | 15200 |

| CP100#80 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 80 | 72 | 80 m/s | 15200 |

| CP100#120 | T27, T29 | 100 x 16.3 | 4" x 5/8" | 120 | 72 | 80 m/s | 15200 |

| CP115#40 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 40 | 72 | 80 m/s | 13300 |

| CP115#60 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 60 | 72 | 80 m/s | 13300 |

| CP115#80 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 80 | 72 | 80 m/s | 13300 |

| CP115#120 | T27, T29 | 115 x 22.3 | 4 1/2" x 7/8" | 120 | 72 | 80 m/s | 13300 |

| CP125#40 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 40 | 80 | 80 m/s | 12200 |

| CP125#60 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 60 | 80 | 80 m/s | 12200 |

| CP125#80 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 80 | 80 | 80 m/s | 12200 |

| CP125#120 | T27, T29 | 125 x 22.3 | 5" x 7/8" | 120 | 80 | 80 m/s | 12200 |

| CP150#40 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 40 | 90 | 80 m/s | 10200 |

| CP150#60 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 60 | 90 | 80 m/s | 10200 |

| CP150#80 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 80 | 90 | 80 m/s | 10200 |

| CP150#120 | T27, T29 | 150 x 22.3 | 6" x 7/8" | 120 | 90 | 80 m/s | 10200 |

| CP180#40 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 40 | 110 | 80 m/s | 8600 |

| CP180#60 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 60 | 110 | 80 m/s | 8600 |

| CP180#80 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 80 | 110 | 80 m/s | 8600 |

| CP180#120 | T27, T29 | 180 x 22.3 | 7" x 7/8" | 120 | 110 | 80 m/s | 8600 |

| Size In mm | Inner Box | Carton | Carton Size(cm) | G.W/kgs | N.W/kgs |

|---|---|---|---|---|---|

| 50x10 | 20pcs/shrink | 500pcs | 28x28x24 | 12 | 11 |

| 100x16.3 | 10pcs/shrink | 100pcs | 55x23x15 | 7 | 6 |

| 10pcs/shrink | 200pcs | 55x23x27 | 14 | 12 | |

| 115x22.3 | 10pcs/shrink | 100pcs | 63x26x15 | 9 | 8 |

| 25pcs/shrink | 100pcs | 26x26x28 | 9 | 8 | |

| 125x22.3 | 10pcs/shrink | 100pcs | 68x28x15 | 11 | 10 |

| 25pcs/shrink | 100pcs | 26x26x28 | 11 | 10 | |

| 150x22.3 | 25pcs/shrink | 100pcs | 32x32x28 | 17 | 16 |

| 180x22.3 | 10pcs/shrink | 100pcs | 98x38x15 | 21 | 20 |

| 25pcs/shrink | 100pcs | 39x39x28 | 21 | 20 | |

| 230x22.3 | 25pcs/shrink | 50pcs | 48x25x28 | 18 | 17 |

Ceramic Flap Discs are created by overlapping coated abrasive flaps and adhering them firmly to a back-up plate.

Cooler cutting and more durable than natural aluminum oxide products, the flap discs provide maximum life while dissipating heat.

This ceramic grain can be used for wet grinding and dry grinding, but it will not burn the workpiece.

They are better than zirconium oxide in every respect(better surface finishing, longer using life and cost-effective).

Shape Recommendation:

Flat flap disc(Type 27): Type 27 Flat flap discs have a flat flap design and provide the best finish. Used primarily on flat surfaces they grind at flatter angles 0° to 15°. T27 Abrasive Flap Discs are the he best choice for blending and smoothing finishing.

Conical flap disc(Type 29): Conical T29 flap discs have angled flaps and may be used on both contoured and edge work. Type 29 Abrasive flap discs are the more aggressive choice, with flaps angles at 10°. Grind at steep angles 15° to 25°. The angle provides greater surface contact for stock removal on flat surfaces. T29 Abrasive Flap Discs are the best choice when speed and stock removal are primary considerations.

Recommended Application:

Ceramic Flap Discs are excellent choices for aggressive stock removal on hard materials.

Suitable for the processing of carbon steel, high-alloyed steel, stainless steel, chrome, cast iron, nickel steel, non-ferrous metals.